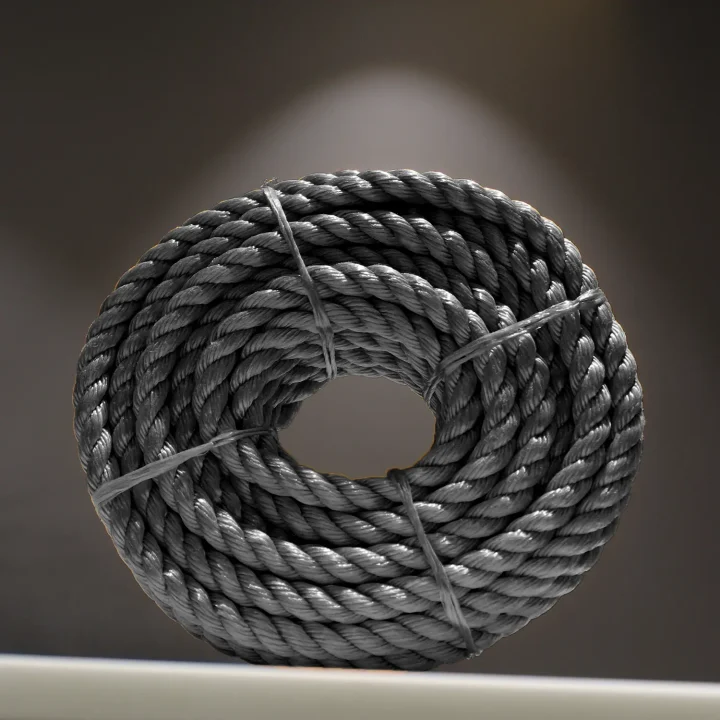

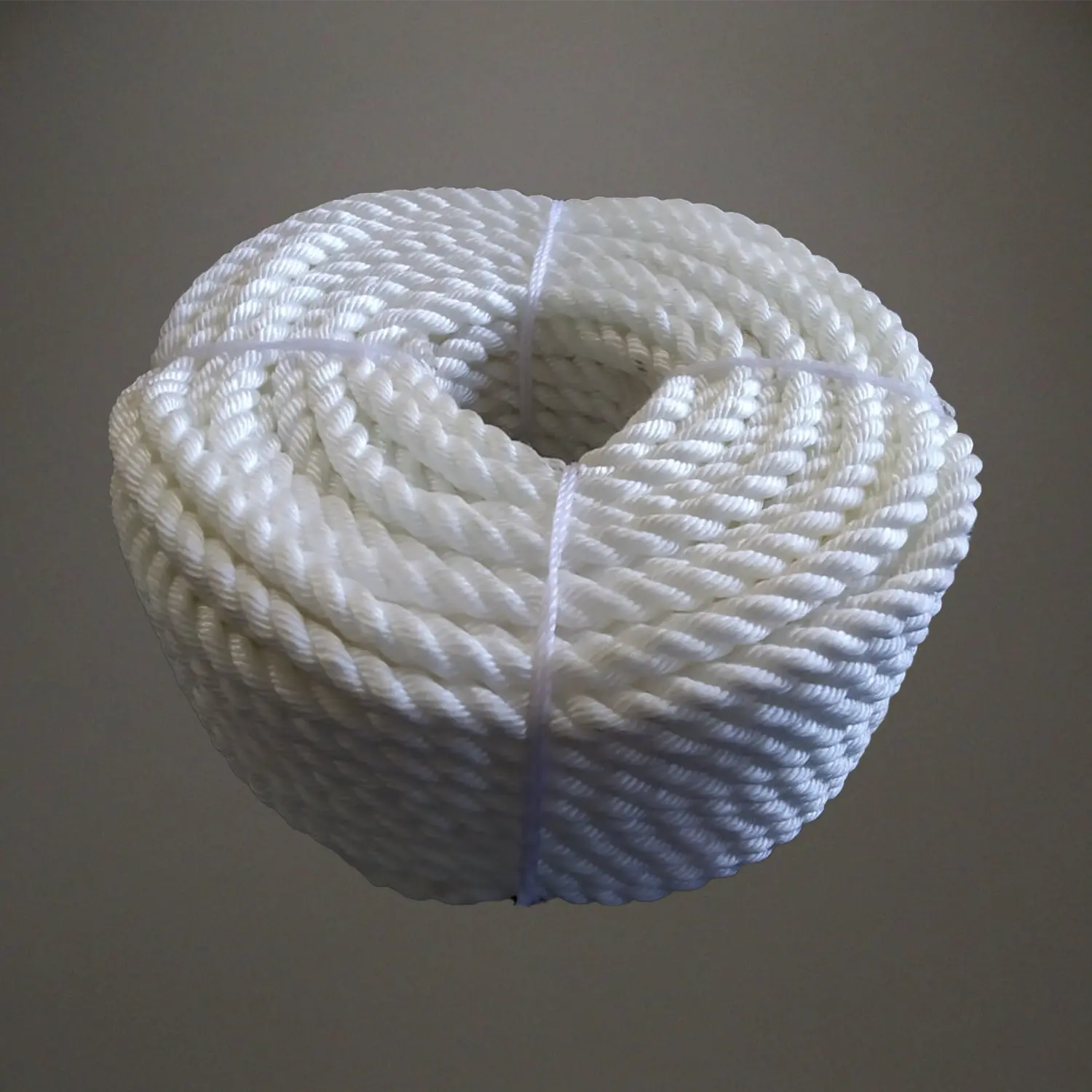

Industrial Twisted Rope

- Home

- portfolio

- PP Danline Rope

- Industrial Twisted Rope

Industrial PP Rope is engineered for heavy-duty industrial applications that require high strength and durability. Crafted from robust polypropylene fibers, this rope is resistant to stretching, fraying, and breaking under significant loads. Its twisted construction provides added strength and flexibility, making it suitable for a variety of industrial tasks such as lifting, securing, and material handling. This rope is also resistant to oils, chemicals, and UV radiation, ensuring longevity and reliability in harsh working environments. Whether used in manufacturing plants, warehouses, or outdoor industrial settings, the Industrial Twisted Rope is a dependable solution that can handle tough jobs with ease.

Characteristics:

- UV Resistant :- Offers excellent protection against ultraviolet radiation, making it ideal for prolonged outdoor use.

- Lightweight & Floats on Water :- Perfect for marine and fishing applications where buoyancy is a necessity.

- High Tensile Strength :- Engineered to withstand significant stress without breaking, ensuring reliability in critical applications.

- Chemical Resistant :- Suitable for use in environments where exposure to chemicals is prevalent.

- Cost-effective & Versatile :- Balances performance with affordability, making it a practical choice for a wide range of industries.

Related Products

Technical Specification :

- Material :- PP Danline

- Rope Construction :- 3-Strand Z Twist

- Lay Structure :- Medium Hard Lay

- Density :- 0.92

- UV Resistance :- Excellent

Range of Rope :

- Diameters :- 2MM to 40MM

- Length :- 110, 220, 330, 440, and up to 660 Meter

- Colour :- Yellow, Black (Mix)

- Rope Balancing :- Good

Specification of PP Ropes – 3 Strand

| DIAMETER | SIZE (MM) | WEIGHT PER MTR | APPROX BREAKING LOAD | COIL WT MTR 220 | COIL WT MTR 500 | COIL WT MTR 1000 |

|---|---|---|---|---|---|---|

| 2 | 0.002 | 45 | 0.440 | 1.000 | 2.000 | |

| 3 | 0.004 | 110 | 0.880 | 2.000 | 4.000 | |

| 5/32″ | 4 | 0.007 | 202 | 1.540 | 3.500 | 7.000 |

| – | 5 | 0.011 | 362 | 2.420 | 5.500 | 11.000 |

| 1/4″ | 6 | 0.016 | 522 | 3.520 | 8.000 | 16.000 |

| 5/16″ | 8 | 0.029 | 912 | 6.380 | 14.500 | 29.000 |

| 3/8″ | 10 | 0.045 | 1353 | 9.900 | 22.500 | 45.000 |

| 1/2″ | 12 | 0.065 | 1928 | 14.300 | 32.500 | 65.000 |

| 9/16″ | 14 | 0.089 | 2650 | 19.580 | 44.500 | – |

| 5/8″ | 16 | 0.116 | 3325 | 25.520 | 58.000 | 116.000 |

| 3/4″ | 18 | 0.147 | 4227 | 32.340 | 73.500 | 147.000 |

| 13/16″ | 20 | 0.182 | 5101 | 40.040 | 91.000 | – |

| 7/8″ | 22 | 0.220 | 6175 | 48.400 | 110.000 | – |

| 1″ | 24 | 0.262 | 7220 | 57.640 | 131.000 | – |

| – | 26 | 0.307 | 8265 | 67.540 | 153.500 | – |

| 1.1/8″ | 28 | 0.356 | 9125 | 78.320 | – | – |

| – | 30 | 0.409 | 9820 | 89.980 | – | – |

| 1.5/16″ | 32 | 0.465 | 10528 | 102.300 | – | – |

| – | 34 | 0.525 | 11180 | 115.500 | – | – |

| – | 36 | 0.589 | 11780 | 129.580 | – | – |

| – | 38 | 0.656 | 12429 | 144.320 | – | – |

| – | 40 | 0.727 | 13050 | 159.940 | – | – |

Tolerance On weight :

- 4mm to 8mm = +/- 10%

- 10mm to 14mm = +/- 8%

- 16mm and above = +/- 5%

Applications :

- Manufacturing

- Industrial

- Construction

- Warehousing

- Material Handling

[ our Workshop ]

Innovating in Our Workshop

Note :

- The minimum breaking load (MBL) should never be considered as the safe working load of the rope.

- Breaking strength quoted relates to the new dry ropes in soft lay construction. In wet conditions these values may be lower.

- Please contact us for information regarding long lengths, special colours and different packing.