Quality control is a critical aspect of rope manufacturing, ensuring that every product meets the required standards for strength, durability, and performance. At Radiance Ropes, we follow a rigorous quality control process that begins with raw material selection and continues through every stage of production.

Raw Material Selection: The first step in ensuring high-quality ropes is selecting the best raw materials. We source polypropylene and HDPE from reputable suppliers, ensuring the materials meet our stringent quality criteria.

Extrusion and Melting: During the extrusion and melting process, we monitor the machinery and conditions closely to produce uniform and consistent fibers. This stage is crucial for achieving the desired properties of the ropes.

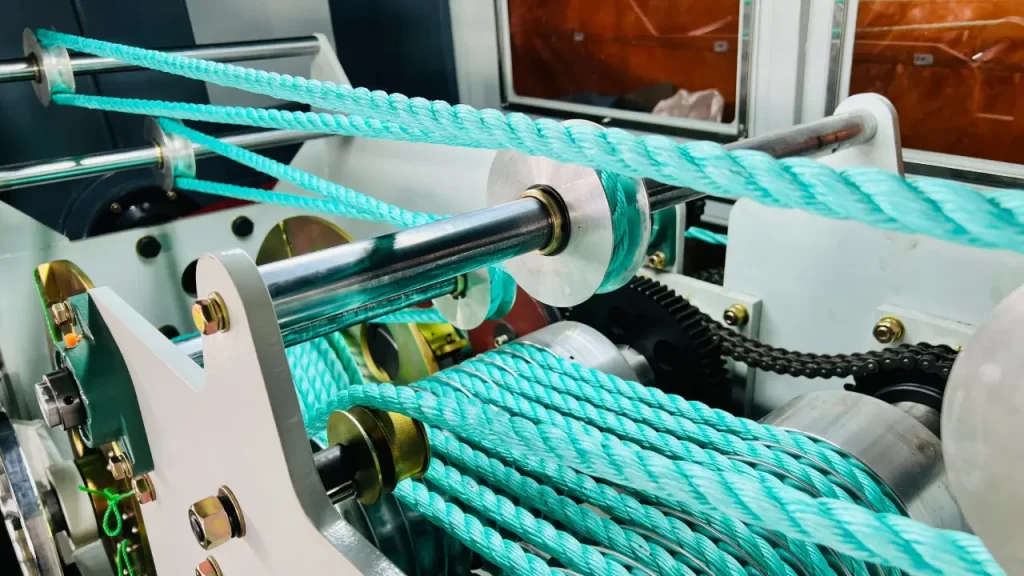

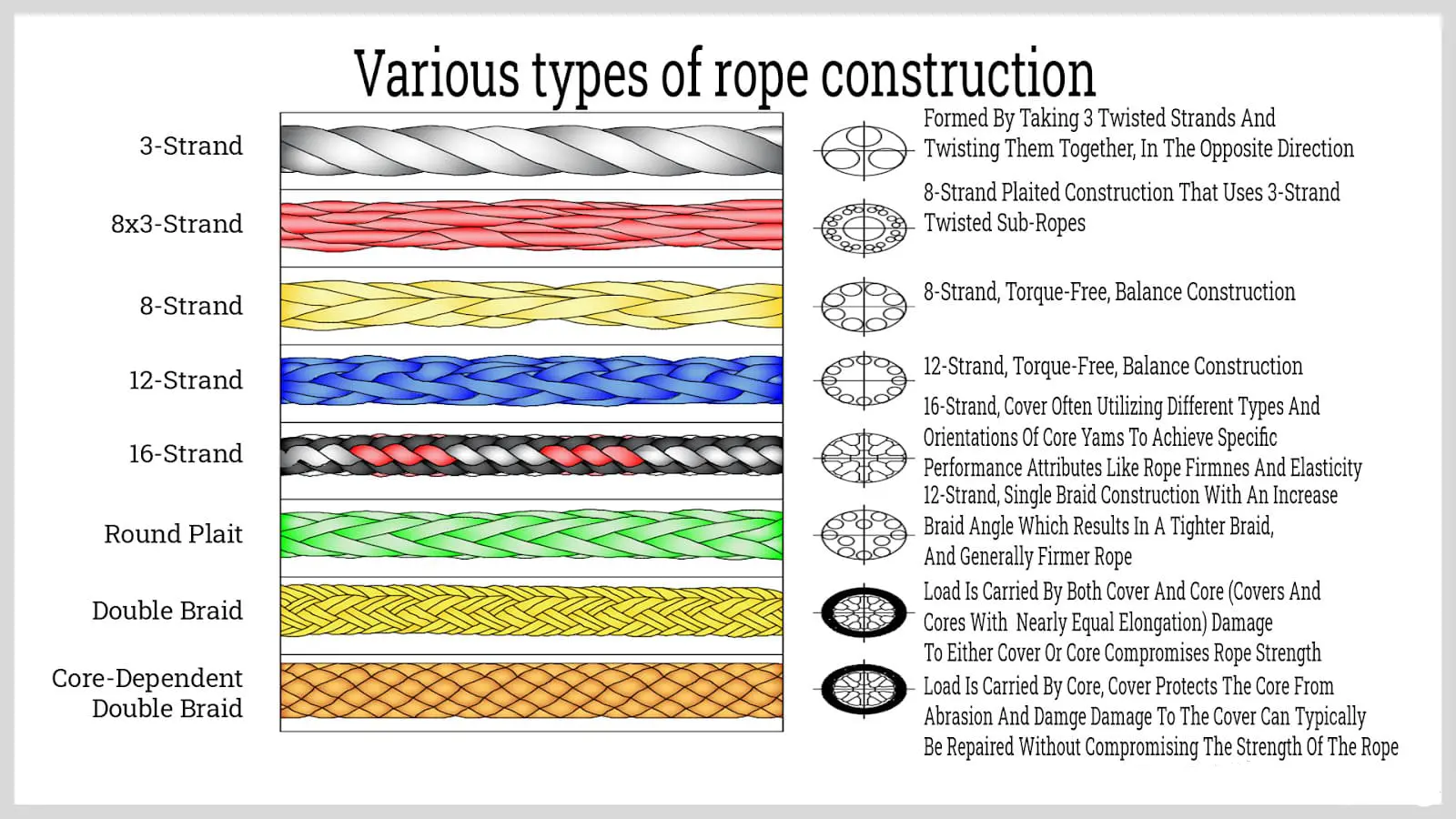

Twisting and Braiding: The fibers are twisted and braided into ropes using precision equipment. Our skilled technicians ensure that the ropes have the correct balance of strength and flexibility, adhering to our quality standards.

Quality Assurance Testing: Each batch of ropes undergoes comprehensive testing to verify their strength, durability, and resistance to environmental factors. We conduct tensile strength tests, abrasion resistance tests, and chemical resistance tests to ensure our products can perform in demanding conditions.

Final Inspection and Packaging: Before packaging, the ropes are inspected for any defects or inconsistencies. Only ropes that pass our stringent quality checks are packaged and prepared for delivery, ensuring our customers receive products that meet their expectations.

This blog explores the various stages of quality control in the production process at Radiance Ropes, highlighting our commitment to delivering high-quality ropes that our customers can rely on.